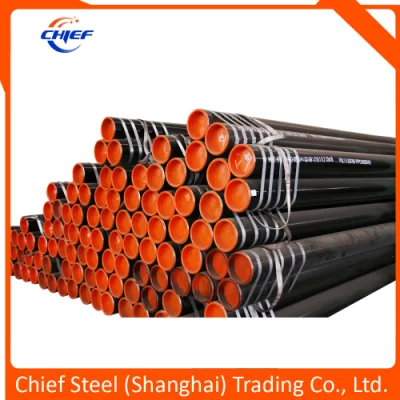

High Frequence Welded Carbon Steel Pipe API5l / ASTM A53 / ASTM 252 /API5CT

High-Frequency Electric Welded (HFW) Pipes1.Technical Parameters 2.Product Showcase 3.Production Facility 4.Quality Cont

Description

Basic Info

| Model NO. | ERW STEEL PIPE |

| Model No. | API5l Psl1/ Psl2 ASTM A53 |

| Surface Treatmen | Black Varnish, 3lpe, 3lpp,Fbe |

| Thickness | 1.5mm-15.8mm |

| Internal Coating | Cement Mortar Lining; Bitumen Coating; Liquid Epox |

| 3lpe/3lpp Standard | DIN30670-1991,Awwac210 |

| O.D | 1/2′′-24′′ |

| Steel Grades | Gr. a Grbx42X46X52X56X60X65X70, L245 etc. |

| External Coating | 3lpe; 2lpe; 2lpp; Fbe; Bitumen; Enamel Tape Hot-Ap |

| Steel Standrad | API 5L-2009; ISO3183-2007;DIN30670 |

| Transport Package | with End Caps, in Bundles by Steel Strips |

| Specification | 1/2" - 24" GR. B, X42, X52, X60, X65 |

| Trademark | Chief Steel |

| Origin | China |

| HS Code | 73061900 |

| Production Capacity | 30, 000ton |

Product Description

High-Frequency Electric Welded (HFW) Pipes1.Technical Parameters| Commodity | HFW welded steel carbon pipeline | |

| Size | O.D | 1/2''-24''. |

| Thickness | 1.5mm-15.88mm | |

| Length | 6m fixed , or 12m fixed, or based on speial request | |

| Standards | API 5L 45th; ISO3183-2007; ASTM A53, ASTM A252, AS1163 | |

| Steel Grades | Gr. A GrBx42x46x52x56x60x65x70,etc | |

| internal coating | cement mortar lining; bitumen coating; liquid epoxy; FBE | |

| external coating | 3lpe; 2lpe; 2LPP; FBE; Bitumen; enamel tape hot-applied; liquid epoxy coating; polyurethane insulated coating. | |

| Manufacture Process | Cold formed | |

| Main Application | The external coating is mainly used for anti-corrosion protection for liquid pipes before burying. Such pipe has been widely used in rugged environment. | |

| Min quantity | 5 tons, more quantity price will be lower. | |

| packing | beveled on both pipe ends, with protector caps, in bundles by steel strips. In hexagonal shape bundles wrapped with strong steel trip 2MT/bundle. with 2 slings on each bundles. | |

| Delivery time | 20-25days after receiving your deposit or L/C. | |

| Payment | TT or 100% Irrevocable LC at sight. We can discuss. | |

| External Coating | |

| Coating type | Coating Standard |

| 3LPE/3LPP | DIN30670-1991,CAN/CSA Z245,21-2010,ISO21809-1-2009 SY/T 0413-2002,GB/T23257-2009 |

| 2LPE/2LPP | SY/T 0315-2002,GB/T23257-2009,ISO21809-1-2009 |

| FBE(Fusion-bond epoxy) | SY/T 0315-2005,AWWA C213-2001,CAN/CSAZ245.20-2010,ISO218909-2-2007,API RP5L9-2001 |

| Bitumen coating Enamel &Tape hot-applied | BS534-1990,AWWA203-2002,AWWA214-2000 |

| Liquid epoxy coating | AWWWA C210-2007 |

| Polyurethane insulated coating | SY/T0415-1996,CJ/T114-2000.EN253-1994 |

| Internal Coating | |

| Liquid Epoxy Coating | AWWAC210-2007 |

| FBE | AWWAC213-2001 |

| Cement Mortar Lining | BS534-1990,AWWA C205-2001 |

| Bitumen Coating | BS534-1990 |

3.Production Facility

4.Quality Control

FAQ

Q1:How about thequality?

A:Third party inspections are always welcomed, like TUV. All of the goods will be released together with MTC and stamped by TPI.

Q2: How long is the delivery time?

A: Generally about 5-10 days if the goods in stock. Or will be 15-20 days if the goods are not in stock. And alsoaccording to the quantity.

Q3:Do you provide samples? Free or not?

A: Yes, we could offer the sample for free but do not pay the cost of freight.

Q4:May I customize the steel pipe?

A:Sure you can, we can produce according to your requirement, you can send the CAD ordesign drawing.

Q5:Any value-added Services?

A:Fottunately for you,we are very experience in this industry. We have equipped our warehouse with the necessitiesto perform in-house painting,coating,pipe cutting, jointed welding, and make machanical fabricate per to request.

Q6: How about the trade terms?

A: EXW, FOB, CFR, CIF, LC will be accepted.

Our Contact

Send now